Art hai yeh. Jo bhi kiya hai dil sey kiya hai Jab tak hamein acha nahi lagta, tab tak hum usey chodtey nahi.1

On an average day Arvind bhai a master clay modeler, informally trained in painting and sculpting by seven gurus (teachers) in his village in the Indian state of Bihar, spends his time painstakingly making ornate murtis (statues) of gods, goddesses, saints, political figures or any of the myriad living beings asked of him by the management of a CNC stone carving factory on the outskirts of Ahmedabad, India. Inseparable from his world of crafting clay with a set of basic tools, his bare hands, and experience is a vast world of computerisation and digital fabrication processes in the CNC factories of the Trivedi Group. In 1997, through a set of densely knitted hand-intensive and automated carving processes, the factory undertook its first CAD-CAM enabled architectural project: the Shree Krishna temple in West Bromwich, United Kingdom (Figure 1). Designed by a hereditary ‘temple architect’ from the Sompura community, which specialises in building carved stone load bearing temples, the shift to digital modes marked a new set of relations in temple design and construction.

This article investigates the transformation in architectural labour brought about by digital modes of representation and fabrication deployed to achieve a certain architectural aesthetic related to a western Indian tradition of temple architecture —colloquially known as the Nagar shaili— that is operationalised in a transnational context. Through accounts of a temple architect, a clay modeler, and a software engineer involved in the design and making of the Shree Krishna temple, it argues that digital modes of production have fundamentally altered architectural labour. However, instead of making traditionally trained labour redundant, the production process relies heavily on these very methods of sculpture, masonry and drawing to produce data for fabrication and for the finishing stages of CNC milled stone. The article highlights the limits of the technology in use by foregrounding adaptations, improvisations, and adjustments, emphasising new understandings of the builders’ relations with both history and technology.2 It brings to the fore new problems as well as the creative interventions of a range of actors, which produce new forms of expertise, qualities, and affects.

Architectural history debates around digital representation and fabrication speak of a struggle contending with the complexity of reproducing temple architecture in a technologically transformed age and in a globally contentious political climate. This struggle is evident in the work of historians of Indian temple architecture writing of transformations of the “Nagara” temple tradition —as it is known in scholarly domains. For example, Adam Hardy, historian of medieval Indian temples writes: “Computer-aided design, with its capacity for cut-and-paste detail divorced from the human hand, and computerised numerical control (CNC) machines, with their ability to cut repeated detail in stone, can be forces for ossification as much as they can potentially open up new creative possibilities.”3 Although there may be some (unspecified) benefits, the terms for how creative possibilities are understood are left ambiguous. The struggle ensues, I suggest, in how the argument seems to be outweighed by what is regarded as ossifications concerned with digital production. In the field of architectural heritage and conservation, which contends with the question of “authenticity” and automation, the terms of engagement seem to be directed towards the extent to which CAD-CAM production contributes to a “loss of the spirit of architecture”.4 The balance of the writings tends towards seeing digital making in terms of polarities: traditional craft against CNC enabled carving. For example, CNC milling machines are deemed to “take over” in the pursuit of saving time and money, handicrafts are seen as being “reduced” to surface treatment, while age-old temple profiles are seen as “industrial replicas”.5 The use of digital production here suggests a regret in losing the authenticity and “aura” of “original” works of art and architecture located in time and place, which prompts questions for this article on how such production can be reframed, reimagined, and actualised in different contexts.6 Despite other valuable accounts of CAD-CAM processes in temple making, machines are seen as representing disembodiment and a “reduction” of craftsmanship.7

I suggest that there is scope to open up prevalent historical accounts to include the struggles, passions, and ingenuities of factory production entangled in technologically mediated works, where workers refuse to ‘bend’ to technical subordination.8 This article asks how the Sompura temple architects, the modellers, the carvers, and the technicians relate to the fundamental transformation they find themselves thrown into and the multiple, contradictory relations entailed with digital technology. In prevalent architectural histories, we might discern a value associated with a “respectful idiom of art”, to borrow from Bruno Latour, obscuring the way that qualities of care and craft that we celebrate in the work of craftsmen working with hand tools continue and extend through bigger and more technologically mediated works.9 After Latour, the rich and complicated stories that are celebrated in hand craftsmanship also provide a powerful vocabulary to think about what people are doing with machinery.10

The use of contemporary technologies by Sompura temple architects, while they position themselves across and between ideas of “antiquity”, is of significance. The subaltern studies scholar Dipesh Chakrabarty’s innovative readings of Heidegger’s “present at hand” (objectified, historicist) and “ready to hand” (pre-analytical, lived) modes of relating to the world are relevant here.11 This framework allows us to see a tactical awareness in the Sompuras which seamlessly straddles the domains of modern histories of the temple —activated in colonial and post-independence arenas— and an everyday production of architecture networked both into the family and places of production, such as the CNC factory.12 This double alignment can be seen in the value assigned by the Sompuras to medieval temples, staking a claim in the modern “history” of “ancient” building traditions while simultaneously viewing them in familial, ancestral terms as handy resources reiterated in contextually embedded designs through new technologies.

Technological artefacts, in this case study, are at the same time in the service of capital, so while the following accounts investigate the industrialisation of temple making, they do not glorify the heady arrival of technology from Italy to India. In the eventful middle ground of socio technical relations, where these accounts are located, I join hands with scholarship that aims to give a fuller view of architectural production, design, and technology.13

Hidden knowledges

Vital and practical knowledges at work in the CNC factory, and other forms of digital labour, are rendered invisible in representations of diasporic architectural cultures. Here digital production remains subjugated by a value placed on an idea of hand craft over machine-made objects. For example, the Shree Krishna Temple’s brochure accompanying its inauguration in 2010 focuses on the manual carving of architectural elements in India, but there is not a single mention of the machinery used for their fabrication.14 The figure of the male labouring body squatting beside ornately carved pieces of stone with hammer and chisel in hand remains at the centre of this visual representation. Studies of the genealogy of such images show that the idealised figure of the craftsman and its representation was generated and valorised in colonial art school ideologies purporting to “arrest the degeneration” of the arts and crafts brought about by industrial means of production.15 As a temple project that was funded by a British diasporic community comprising of East African Gujaratis, these images may be operative in conceiving an imaginary state in which representations of carvers and ornately carved stone are suggestive of a particular idea of India: as a place of “originary” moments of production. The brochure images draw our attention to the value placed on the handmade object, and provide glimpses of the relationship between belonging in a diasporic context, selective representations of making, and actual fabrication processes. However, these representations obfuscate a richer and more complex production process involving new kinds of technology and labour.

In the following sections, I will be providing accounts of three individuals working in the Trivedi CNC factory whose contributions challenge traditional representations of Indian temple design and construction. Each of these individuals has experienced the shift in production first-hand —from largely manual drawing and crafting practices to those around digital modes— and offers a world view at the human-machine interface that complicates, queries, and enriches accepted dichotomies of “technology versus tradition” and “craft labour versus automation”.16

The Sompura temple-architect’s story: creative adjustments

Virendra Trivedi Sompura is a hereditary temple architect as well as a qualified civil engineer. He belongs to a paradigm which is different to the professionalised institution of architecture in India. Sompura considers that his informal training in drawing, design and vastushastras (building codes) with his late grandfather, Amritlal Mulshankar Trivedi, was foundational. His grandfather is known, amongst many other works, for leading the restoration of the ornate 12th-13th century Dilwara temples, at Mount Abu, in the 1950s. Nearly one hundred shilpis (sculptors) from the Sompura community lived on site for twelve years and restored the temples under his direction. The family holds informal archives from this period and beyond, comprising of measured drawings, plaster of Paris models, and sketches, prepared painstakingly as tools to think through material practices of renovation. For new conceptions, drawings preserved in the family home range from scaled layouts to full size drawings of architectural elements detailing carving patterns for production (Figure 2). Sompura recalls drawing the latter with his father and grandfather, before the advent of computer drawing, crouched on all fours over taped sheets of brown paper which covered the floor space of entire rooms. This manual drawing practice is largely redundant due to the shift to computer drawing. Some practitioners, however, still prefer to work off full size prints laid on the floor to judge the “scale” of what they are drawing digitally against their own bodies. In Figure 3 we see Manoj Trivedi Sompura, a temple architect, coming to terms with architectural scale by drawing over a full-size printout of a digitally drawn element. In this way, some practitioners link new digital practices to pre-existing drawing methods in deeply embodied ways.

Figure 2.

Full scale production drawing c. 1985 preserved in the Trivedi Sompura family home in Ahmedabad.

Figure 3.

Temple architect Manoj Trivedi Sompura manually alters a full-scale print-out to contend with architectural scale.

During my fieldwork, Virendra Trivedi Sompura spoke about how the drawings in the family archive, where possible, are continuously being digitised for CAD libraries so that his grandfather’s works and ideas can be preserved and used for current projects. Sompura is approaching the archive, both of the drawings in his home and of actual medieval temples as a practitioner, with a sense of futurity in the present: how best can past examples be used and reassembled in new creations to serve the present is important to him. A good example of using the “archive” of extant medieval temple architecture is the ghatapallav (pot and foliage) detail on an external column at the Shree Krishna Temple (Figure 4). This detail was based on the ghattapallav of the 11th century Kiradu temple complex in Barmer, Rajasthan (Figure 5). Virendra Trivedi Sompura first drew a free hand sketch at a small scale. This, he said, was from his own dimag (intelligence) and experience and not a direct copy of the precedent. This sketch was scanned and then used as a basis for a line drawing prepared in AutoCAD drafting software, using the “PLine” command. To demonstrate this iterative process concerning free hand and digital formats, we may turn our attention to Figure 6 and 7. (Note: these drawings, shared by Virendra Trivedi Sompura, are categorically not of the Shree Krishna temple, but exemplify the process he went through).

Figure 6.

An example of a free hand sketch of a Ghatapallav detail drawn by temple architect Virendra Trivedi Sompura (Image courtesy: Virendra Trivedi Sompura).

Figure 7.

AutoCAD drawing of the Ghatapallav based on the freehand sketch in Figure 6. (Image courtesy: Virendra Trivedi Sompura).

The Sompuras hold extensive CAD libraries of architectural elements which are reproduced either from drawings produced by immediate ancestors, from photographs of medieval precedents, or are new creations altogether. Each time a new project is initiated, architectural profiles and carving details are used from the CAD library and modified digitally or manually to suit each context. Understanding medieval architecture through site visits, familial drawing archives, photographs, historical texts and websites; digitally scanning, tracing, copying, pasting, mirroring, scaling, modifying, re-imagining, are important to the Sompura community as practices of learning and continuity as much as they are ways of dealing with new contingencies, with immense scope for creative play and freedom.

When the Shree Krishna Temple trust approached the Trivedi Group, it was with a shoe-string budget. An idea of progress, informed by economy, underpins the design of the temple. This plays out in a number of ways. For a start, instead of an “evolutionary” and “emanatory” interpretation of Indian temple designs, Sompura and his client simply return to the idea of the site and the community as concrete entities.17 Sompura explained that it was decided collectively to leave out the all-important articulation of the shikhar18 for future generations to raise funds and embellish as they so wish (Figure 8).

In the Nagara architectural tradition, numerous instances from extant temples have four subsidiary shrines on the periphery of a main shrine, for example at the 12th century Jasmalnath Mahadev temple at Asoda, Gujarat (Figure 9). This is known as the Panchayatan (five shrine) configuration and houses a specific combination of five Hindu deities. Due to weather constraints in the United Kingdom, Virendra Trivedi Sompura has brought the subsidiary shrines inside the fabric of the temple in an innovative manner which re-configures the experience of the Panchayatan temple. We can deduce from the plan (Figure 10) that the subsidiary shrines are digitally replicable entities rotated at ninety-degree angles. While facing deities placed in these shrines, at no point does the worshipper turn their back towards other deities. This spatial configuration encourages a rotational, clockwise, movement in worshippers, which mirrors the direction of the replicated carving pattern on the columns (Figure 11). Sompura creates an unusual layout, encouraging an embodied experience centred around the main shrine, and where digitally replicated elements configure a different spatial experience.

The shift to a digital mode of drawing expedited and expanded the Sompuras’ existing manual system for managing their buildings’ designs. Colloquially known as the “layer drawing system”, drawn on several layers of trace paper, Virendra Trivedi Sompura’s family has used a building management and information system since the mid 1970s, connecting design information to production information, to bills of quantity, to construction sites and finally, to on-site assembly. With the shift to AutoCAD in 2007, each stone course is drawn in a separate digital “layer” within the software’s interface (Figure 12), while each stone in a “layer” is dimensioned along its cutting profile and named individually so as to account for every building block.19

I wish to emphasise in this account that while temple architects have adjusted their practices to new modes of digital drawing, which alter not only the way their buildings are experienced, but also how information is produced for manufacture and assembly, these systems are also inextricably linked to pre-existing design, drawing, management, and production habits. Virendra Trivedi Sompura described the design process of creating the Panchayatan temple for the UK in Hindi: “thoda adjust kiya hai, koi dikkat nahi”: we have adjusted [the architectural tradition] slightly, and it is no problem.

The clay modeler’s story: despair and care

Nestled within the heart of a utilitarian concrete and steel-framed warehouse, a few hundred metres away from the actual factory floor is the makeshift workspace of master clay modeler Arvind bhai. When I met him in 2018, the temporary workspace comprised a desk, a drawing board, a chair, a shelf, and a partition made from reclaimed timber boarding (Figure 13). On the day of my visit, his desk was full of wet clay; he was in the process of making the arms and hands of murtis of the Hindu divinities Ram, Lakshman, and Sita with a few basic tools. Close by was a colour photocopy from which he was working the proportions of these figures. Arvind bhai works off drawings or photographs that clients have forwarded to the factory. As part of the technicalities of form making, capturing the correct bhav (emotion) for his clay figures is a central aspect that preoccupies his labour and devotion (Figure 14). Across from his workspace was his puja space (worship alter), and work occurred in close proximity to the gods.

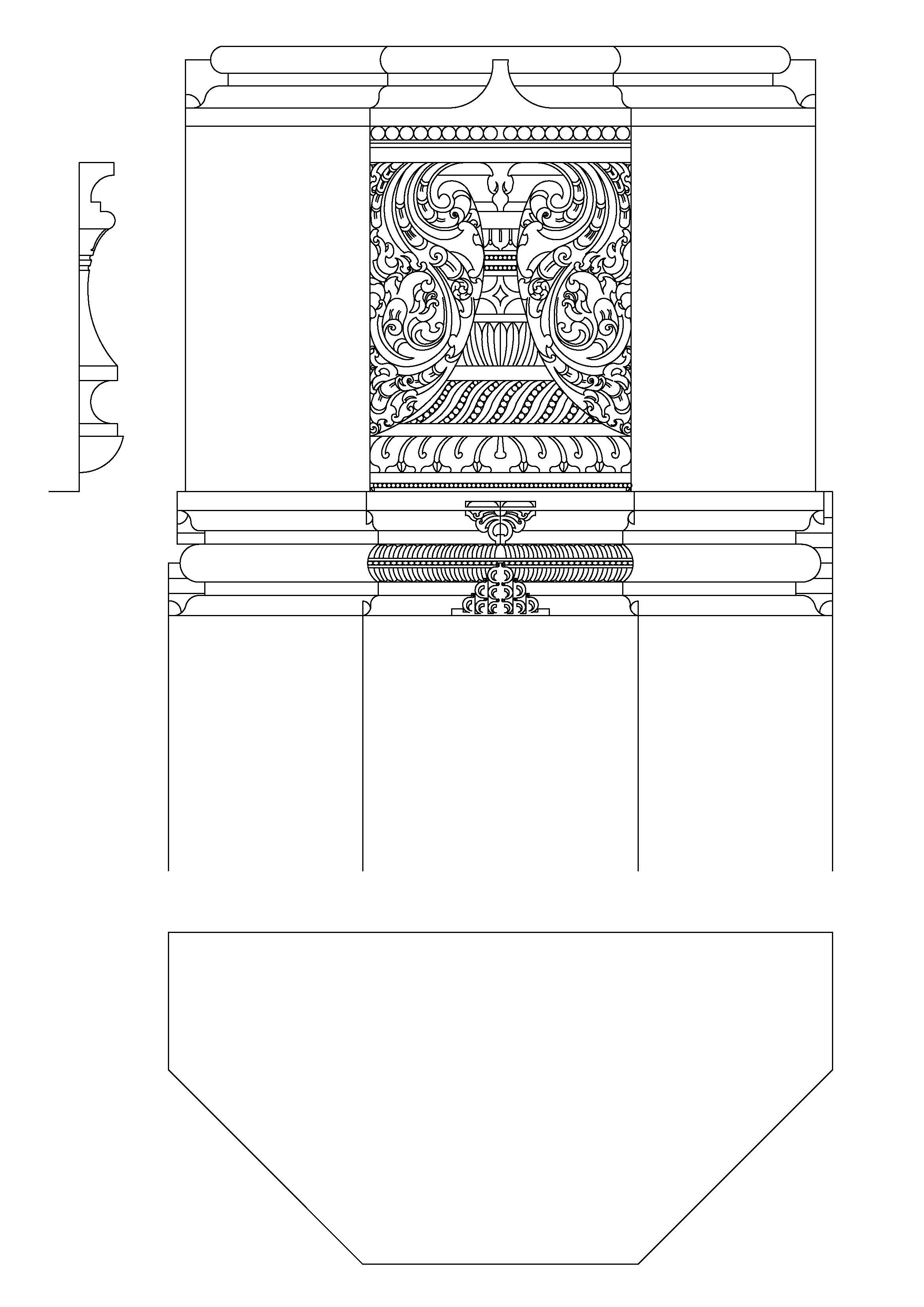

What Arvind bhai does adds profound value to the workings of the factory. The three-dimensional shapes of clay sculptures he makes are deemed too complex to draw in AutoCAD, the drafting software that the factory uses. Once his works are completed, they are scanned using a 3D scanner. The scanned data can be scaled up or down and is then converted into a numerical language format by software programmers employed by the factory (Figure 15). This data enables the carving of figures in stone by CNC machinery. Once carved, these stone sculptures are polished by hand using a combination of hand held power tools and emery stone to remove ridges left by the machine tool, and then finished to exacting standards by skilled stone carvers—once again bringing out the bhav that Arvind bhai started with in his clay model. For the Shree Krishna Temple, built before his time at the factory, this technique was employed to make clay models used to CNC carve several stone panels of Hindu mythology embedded in both the external and internal walls (Figure 16). Similarly, the carving on the columns, beams, and the flat ceilings drawn in AutoCAD by Virendra Trivedi Sompura were first modelled in clay before being 3D scanned and milled by CNC machines (Figure 4).

Each clay sculpture takes him about three weeks to complete, and the kind of haptic control required is one which is impossible to draw from scratch with a mouse on a two-dimensional interface. Arvind bhai’s work already signifies a limit to the technology at use in this factory and the ways in which solutions have been arrived at in negotiating these limits. What Arvind bhai produces cannot be experienced by eye alone and has to be modelled in clay, felt with fingers, before being approved, scanned, and converted to a numerical language.

Along with the love of his craft, his story also brings out the notion of displacement of his own labour. Once the scanning process is over Arvind bhai explained that his work is useless, of no value, as innumerable copies can be made either to the same size or scaled up and down. He used the Hindi word bekar (waste) to express the redundancy of his sculptural work within the logic of the CNC factory. When asked how he felt about this redundancy, he said it pained him. He used the Hindi word dard (pain) to explain that it saddened him to see his craft piled up waiting to be disposed of. Interestingly, he did not see his work as the creation of data, rather, for him it represented berozgari (unemployment) at the level of society. Although he did not say it directly, Arvind bhai seems to be anticipating his own unemployment, ironically, through his own labour. These new methods of digitally extracting manual labour have thrown the relationship between the traditionally trained sculptor and sculpture into a kind of crisis, where the sculpted artefact is no longer the end product, but a means to an end. What happens to the scanned “data” is out of his sight and control, emerging a few days later as a CNC carved stone sculpture, eventually polished and finished by someone else.

Unexpectedly during my visit, he took me to a dump-yard behind the warehouse, which had hundreds of clay samples crafted by him, cracked in the sun, waiting to be discarded. Ruefully he went through the pieces of discarded sculptures. One index of his attachment to his own work can be discerned by his story of covering the clay statue of the goddess Saraswati with a plastic sheet (Figure 17). Arvind bhai explained that a few passing men had smeared coloured pigment on the face of the statue of this goddess, on Holi, the festival of colour. They had not only coloured her face but filled the parting of her hair with pigment, an Indian practice denoting married status for women. It was inappropriate for him that men had touched a revered goddess in such a way, and to prevent this from happening again, he decided to cover the work.

I wish to emphasise here that these discarded works are invested with enormous sense of ownership and affection, as if they are alive. The clay sculpture of the goddess Saraswati is not ritually consecrated, and will never be, for it is the CNC carved stone sculptures that will ultimately be installed and consecrated in places of worship. Yet the dump-yard is equally venerated by Arvind bhai and in a sense reactivates a wasteland that is created by the productive system of capitalism. This shift creates a range of new affective relations where the sculptor is compelled to reframe the value of their craft in the face of digital reproducibility. Folded into these new data processes are acts of veneration to discarded sculpted works.

I suggest that while Arvind bhai’s work has profound importance for the factory, it is not the success of technology that is rendering figures like him berozgar, but perhaps it is due to a failure of the politics of technology. When users adjust themselves to new technologies, as Jonathan Hale reminds us, questions of technology take us from aesthetics to ethical and political realms.20 His contribution could potentially be expanded so that scanners, computers, or CNC machines are part of his creative process and source of pleasure as much as the sculpture. This would involve imagining a new sense of collectivity, belonging, and digital consciousness for Arvind bhai. His current contribution suggests that, in some cases, digital technologies can contribute to an “extractive” dynamic of production, in the sense that design and labour can be captured (and remunerated) for the creation of a single “original” used for serialised manufacture. This is not unique to this stone factory. The question of how original design is valued in an age of saleable and replicable data is a more universal one.

When I asked Arvind bhai about the draw to the factory, while being away from his family for most of the year, he said that he had been working there for fifteen years and accounts this pull to the factory owner, whose temperament he liked very much. He also spoke about the love he received at the factory.21 He then spoke about putting his heart into his work and about having the freedom to work to his satisfaction.

Many of his works were also placed inside the warehouse for the explicit purpose of showing visitors and clients the various stages of production, and for these he was given full credit. I wish to emphasise that Arvind bhai has made a choice, and accepts the contradictions entailed in the CNC production, as it has given him the space to do what he enjoys most and— despite his increasingly precarious position— appreciation from the factory owner, the management, and his peers.

The software engineer’s story: adjustment and improvisation

If Arvind bhai’s story brings out notions of affection and a love of craft, as well as senses of loss and displacement simultaneously, Nimesh Shah’s story, a software engineer and production manager, gives an account of improvisational uses of the machinery for the carving of the Shree Krishna Temple. It reveals an idea of the canny in the way he has managed to bend rules regarding the machinery’s use as well as its very composition.22 Built into his story is also a subtle displacement of the normative idea that the use of high technology imported from the West must conform to its intended uses.

Throughout my interactions with him, Shah emphasised how, during the processing stages of the Bansipahadpur stone, he had to stretch the capacity of the machine to enable it to perform ornate carving. This is in the context of milling ornate jalis (perforated screens), complex ceiling forms of the mandap (the pillared hall), the shikhar, pillars, beams, gateways, and figurative sculpture through CNC machinery. These machines, according to Shah, were originally intended for more basic milling of bathroom and kitchen worktops and architectural mouldings. Shah described this process, in English, as getting “the best out of the machine” and “taking” work out of it, suggesting that it is the machine that is made to work. I aim to highlight an idea of innovation and improvisation in the way CNC milling machines are not just put to use for the purpose they are designed but are themselves manipulated and repurposed to achieve a desired architectural aesthetic.

The innovative interventions beyond the machine’s intended limits were firstly physical. The limitations in the original 3 and 4 axis machines were overcome by allowing the carved objects to be shifted and rotated during the carving process. Secondly, Shah manually generated programmes as the software compatible with the CNC machines did not have the capacity to generate three dimensional forms beyond the x, y, and z planes. He also used parametric programmes to generate machine commands to make architectural forms such as the inner ceiling of the mandap (Figure 18).

Shah trained as a software engineer in the metal industry, joined the Trivedi Group in 1997, and related his story as production manager. The Group needed an expert to set up the CNC factory and provide training in both software programming and operating machinery as well as for managing all aspects of production using CAD-CAM processes. The first CNC machines arrived in the factory from Italy in September 1997: a CMS Brembana 3 axis machine for milling and lathing stone, a GMM Radia, and a GMM Axia machine for profile and angle cuts. Many of the individuals Shah came to train did not speak or read English, and some did not have a basic education. However, in Shah’s story, each individual and process is valued. From using the scanner, to creating programmes for production, to setting the stone on the machine bed, to operating the machinery, to maintenance, to dry assembly, to packaging the fragments in a particular way to avoid breakage. Shah emphasised skill and care in every step.

At the Trivedi factory, Shah recounted the difficulties of drawing a complete temple on AutoCAD revision 10 running on MS DOS where the drawing commands had to be given through lengthy sequences of written script. This was a labour-intensive process as each building block for the temple was drawn separately for production. The most substantial challenges came after the drawing stage, when the software compatible with the machine did not provide 3D simulation. The manually generated programmes were created without visual appreciation.

Shah oversaw the making of clay models not only of figurative sculpture, but also carving patterns on architectural elements such as columns and beams. The complex ceiling above the mandap was based on fiberglass models cast from stone carved samples of single elements which, scanned and combined with Shah’s parametric program, generated the base information for carving the whole ceiling. The jalis, which were carved from single pieces of stone, presented a technical challenge in tooling as the machine did not come with readymade tools suitable for jali work. This involved making customised carving heads for the CNC machines in the Trivedi Group’s own workshops.

Nimesh Shah is not just using a tool out of the box, but there is a cunning modification at work here. He stretches the machine’s capacity, so much so that the manufacturers of the machines were themselves taken by surprise. The architectural forms of the temple were thought to be unachievable by the machine manufacturers themselves. In his words: “the Italian guys did not know about Indian art and had no idea that this type of work could be achieved by their own machines”. Many of the Trivedi Group’s products started appearing in the CMS brochure from 2000. Today the Group makes an appearance as a detailed case study on CMS’s website where themes of versatility and accuracy of the machines are considered paramount to the Group’s success. Shah’s narrations on the other hand make us aware that such notions of versatility have a far more complex, embedded and multifaceted history.

Conclusion: “Thoda adjust kiya”

Going back to Virendra Trivedi Sompura’s Thoda adjust kiya (we adjusted slightly) is a useful way to end this paper, for it draws our attention to the inevitability of change in relation to technologies. This phrase has a double meaning. It alludes to the idea that not only have the makers adjusted to new technologies, but that they have adjusted the technologies to meet their needs. Thus, the article underscores the limits of technologies in the fabrication of the Shree Krishna temple and the creative interventions required to achieve a certain aesthetic related to a long temple tradition, in turn, adjusting the aesthetic and its experience itself.

Thoda adjust kiya also underplays the scale of the many small shifts made in the process, which have created their own range of qualities, affects and meanings in how people understand their own work. As we have seen Virendra Trivedi Sompura, the temple architect, has adjusted a building tradition to the UK context spatially, climatically, and to new technological processes within a hereditary tradition. Arvind bhai, the clay modeler, adjusts to the reproducibility of his own labour through acts of veneration of his original work. Nimesh Shah, the engineer, adjusts emerging machine processes from their intended uses through improvisational uses of the machinery, custom programming, and tooling methods that extend beyond the machine’s intended uses.

These adjustments complicate, query, and enrich accepted dichotomies of “technology versus tradition” and “craft labour versus automation”. The builders’ ideas about innovation, improvisation and pragmatics are actively adjusted and re-interpreted via contemporary technologies. These builders do not view themselves as delivering designs based on an “evolutionary” and “emanatory” interpretation of the history of Indian temple architecture. Rather, their relationship with history and technology seems both tactical and pragmatic.